AL7075-T6: Key Properties, Advantages, Disadvantages, and Comparison with AL6061 & AL5052

AUTHOR: Creallo Marketing Team|2025.11.12

Aluminum is a lightweight metal with relatively low strength in its pure form. Because it is softer and more vulnerable to deformation than many other metals, various industries commonly use aluminum alloys, which combine aluminum with other alloying elements to improve mechanical properties.

Among these alloys, AL7075-T6 is a high-strength aerospace-grade material widely used in aviation, defense, robotics, and sports equipment. It offers an exceptional strength-to-weight ratio and is strong enough to replace steel in certain load-bearing structures.

This article explains the key characteristics, advantages, and limitations of AL7075-T6, as well as how it compares to AL6061-T6 and AL5052, helping you choose the most appropriate material for your project.

What is AL7075-T6?

AL7075 is a 7000-series aluminum alloy primarily strengthened with zinc (Zn), with additional magnesium (Mg) and copper (Cu).

Through T6 heat treatment, its mechanical properties are further enhanced, making it one of the highest-strength aluminum alloys available.

- Density: approx. 2.81 g/cm³

- Weight vs. steel: ~1/3

- Typical industries: aerospace, defense, racing, robotics, drones, sports equipment

Advantages of AL7075-T6

Exceptional Strength

AL7075-T6 provides a tensile strength of approximately 570 MPa, ranking among the strongest aluminum alloys.

For comparison, AL6061-T6 offers around 310 MPa, meaning 7075 is nearly twice as strong.

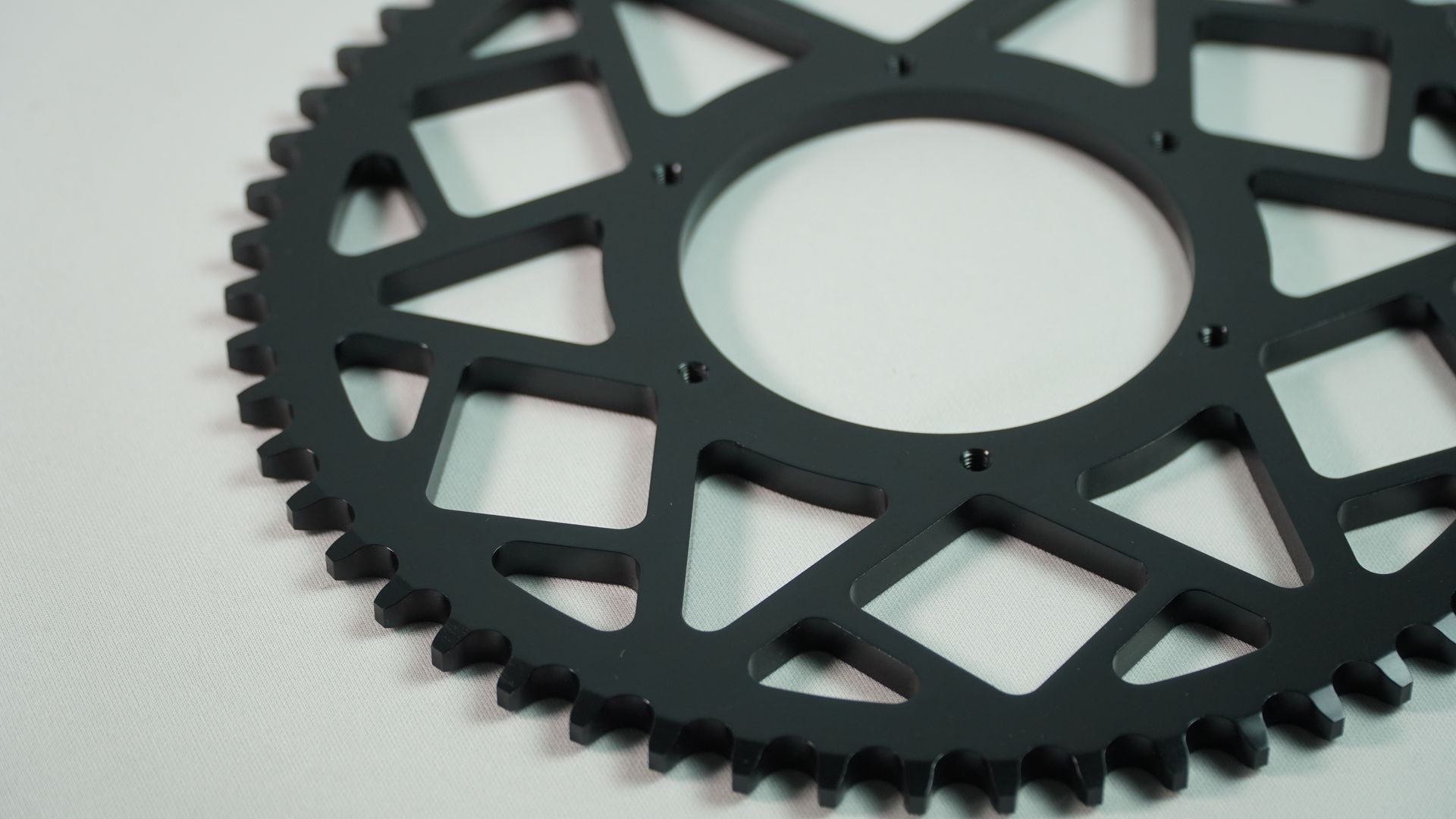

Thanks to its high strength and low weight, AL7075 is widely used for high-load components such as brackets, arms, joints, and structural frames.

Outstanding Strength-to-Weight Ratio

AL7075 is recognized for having one of the best strength-to-weight ratios among aluminum alloys.

This makes it ideal for lightweight yet high-strength applications such as robotic arms, drone frames, and motorsport components.

Good Machinability for a High-Strength Metal

Although AL6061 offers the best machinability among aluminum alloys, AL7075 still machines well compared to other high-strength metals. It cuts more easily than stainless steel and produces less tool wear.

Disadvantages of AL7075-T6

Relatively Low Corrosion Resistance

Unlike pure aluminum—which naturally forms a protective oxide film—AL7075 has lower corrosion resistance compared to AL5052 or AL6061. Its copper content makes the alloy more sensitive to intergranular corrosion and stress corrosion cracking, especially after heat exposure.

✔ Mitigation

- Apply anodizing (hard anodizing recommended)

- Use protective coatings or painting

- Avoid unprotected use in marine or outdoor environments

Poor Weldability

AL7075 is prone to solidification cracking during welding due to shrinkage during cooling.

For this reason, welding is generally not recommended, and components are typically manufactured via CNC machining or bolted joints.

Higher Material Cost

Because of its superior strength and aerospace-grade performance, AL7075 is more expensive than AL6061 or AL5052.

Comparison: AL5052 vs AL6061-T6 vs AL7075-T6

Below is a quick comparison frequently requested by engineers and product developers.

Property Comparison

| Category | AL5052 | AL6061-T6 | AL7075-T6 |

|---|---|---|---|

| Strength | ★★★ | ★★★★ | ★★★★★ |

| Corrosion resistance | ★★★★★ | ★★★★ | ★★★ |

| Machinability | ★★★ | ★★★★★ | ★★★★ |

| Weldability | ★★★★ | ★★★★★ | ★★ |

| Cost | Low | Medium | High |

| Highlights | Best corrosion & formability | Most versatile | Highest strength |

Application Examples

AL5052

Excellent corrosion resistance and formability make AL5052 suitable for environments with moisture or salt exposure, as well as thin-sheet and bent structures.

Typical uses:

- Marine and outdoor housings

- Electrical/telecom enclosures

- Sheet-metal brackets and panels

AL6061-T6

Balanced mechanical properties and excellent machinability make AL6061-T6 a widely used general-purpose alloy for CNC machining.

Typical uses:

- Robot & industrial equipment frames

- Vehicle and drone structures

- General mechanical parts

AL7075-T6

With its superior strength-to-weight ratio, AL7075-T6 is selected for high-load mechanisms and high-performance components.

Typical uses:

- Aerospace structures

- High-load mechanical brackets & joints

- Racing & drone high-performance parts

Material Selection Guide

- Highest corrosion resistance → AL5052

- Best balance of cost, strength, and machinability → AL6061-T6

- Maximum strength & lightweight performance → AL7075-T6

Machining Considerations for AL7075-T6

AL7075’s high strength makes it more demanding to machine than standard aluminum alloys.

For stable and precise results, consider the following points:

- Apply internal corner radii of at least R0.5–1.0 mm

- Use tools optimized for fast chip evacuation

- For complex or high-precision geometry, 5-axis CNC improves quality

- Expect color variation during anodizing

- Confirm T6 heat-treatment requirements during design

AL7075 CNC Machining with Creallo

Choosing the right alloy is just as important as selecting the manufacturing process.

Because aluminum alloys differ significantly in strength, weight, corrosion resistance, and machinability, material selection directly affects product performance, manufacturing cost, and overall development quality.

Creallo supports CNC machining for AL5052, AL6061-T6, and AL7075-T6, offering AI-based manufacturability checks and instant quotations in under 1 minute simply by uploading your 3D file.

With ISO 9001, 14001, and 27001–certified quality, environmental, and information-security systems, we deliver reliable and secure manufacturing services from prototype to low-volume production.

- Discover Our CNC Machining Services →

- Browse Supported Metal Materials →

- See CNC Manufacturing Examples →