What Is Aluminum AL6061? | Strengths, Weaknesses, T6 Heat Treatment, and Comparison with AL5052

AUTHOR: Creallo Marketing Team|2025.07.29

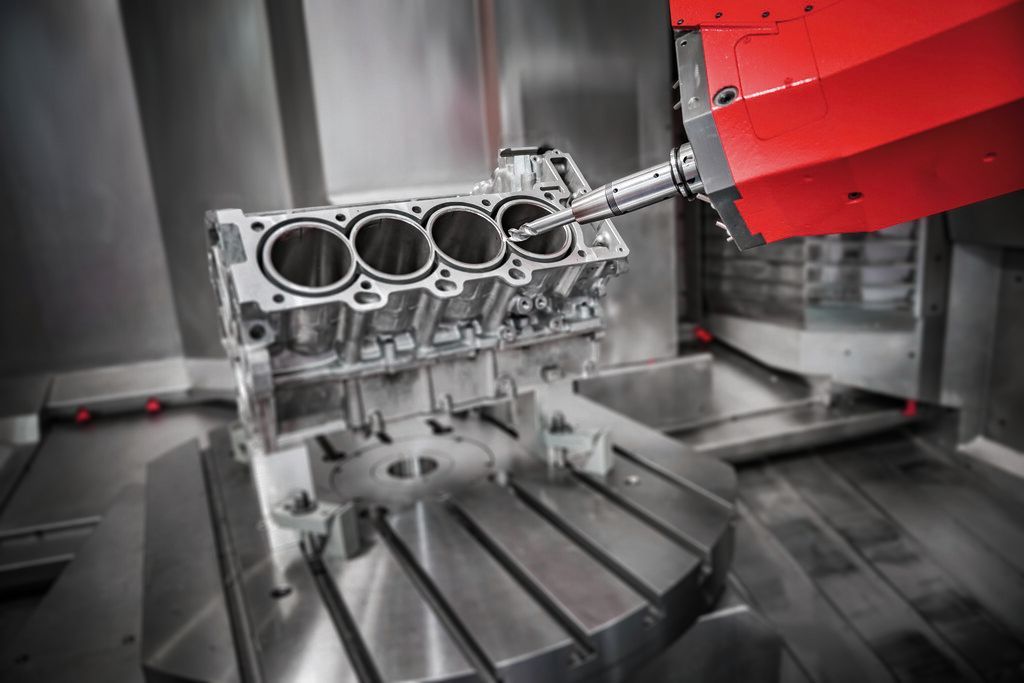

Aluminum used in CNC machining is typically an alloy. This is because pure aluminum is relatively soft and prone to damage, offering low strength compared to other metals. To overcome these limitations, aluminum alloys are created by combining aluminum with other metal elements. These alloys vary in properties like strength and corrosion resistance and are classified into series from 1000 to 8000.

Since each aluminum alloy has different characteristics, it is important to choose the right type based on the intended use of your product.

In this article, we’ll take a closer look at AL6061, a 6000-series aluminum alloy that is the most frequently ordered material on Creallo’s real-time CNC machining quote platform. Let’s explore its features, advantages, and drawbacks in detail.

Key Characteristics of AL6061

AL6061 is a 6000-series aluminum alloy that contains magnesium and silicon. Thanks to its excellent corrosion resistance, it is widely used in outdoor structural applications. Its durability against environmental exposure also makes it ideal for use in ships, vehicles, and other parts frequently exposed to water, salt, and harsh weather.

Advantages of AL6061

Excellent Corrosion Resistance

AL6061 does not easily rust, even in extreme environments. While all aluminum forms a protective oxide film when exposed to oxygen, the magnesium in AL6061 enhances this process, making the material more corrosion-resistant than many other alloys.

Increased Strength via T6 Heat Treatment

T6 heat treatment is a widely used aluminum treatment method. It involves solution heat treatment followed by artificial aging, without any cold working. When AL6061 undergoes T6 treatment, copper and magnesium precipitate to significantly increase the material’s strength. The tensile strength of AL6061-T6 can be approximately 2.5 times higher than that of non-treated AL6061.

Excellent Forgeability

Forging involves shaping heated metal using compressive force. Among aluminum alloys, AL6061 is one of the easiest to forge, making it suitable for mass production and high-volume applications.

Disadvantages of AL6061

Lower Strength Without T6 Treatment

If AL6061 is not T6 heat-treated, its strength is relatively low among aluminum alloys. If your application requires high strength, you should consider whether untreated AL6061 is appropriate.

Prone to Surface Damage

Aluminum is a relatively soft metal, so its surface can be easily scratched. The hardness of AL6061 is about 30HB, which is lower than that of general-purpose AL5052 (around 47HB). As a result, it’s more vulnerable to abrasions or contact damage.

Use Cases for AL6061

AL6061 excels in structural applications where strength is important and where welding is required. Common use cases include:

- Vehicle frames and chassis

- Structural components in aircraft

- Bicycle frames

- Marine and coastal engineering applications

Frequently Asked Questions (FAQ)

Q. What’s the difference between AL6061 and AL5052?

A. AL5052 has moderate strength and excellent corrosion resistance, especially in saltwater environments. It also offers great weldability and is often used in storage tanks, marine equipment, and food processing systems. AL5052 may be more affordable depending on market conditions.

On the other hand, AL6061 can be heat-treated to enhance its strength and has excellent machinability, making it suitable for complex parts and structures. Its high fatigue resistance is ideal for applications involving repeated stress.

Q. Is heat treatment required for AL6061?

A. It depends on the application. For structural components requiring strength, T6 heat treatment is highly recommended. It makes a significant difference in mechanical properties.

Q. Why is AL6061 widely used in CNC machining?

A. AL6061 offers a great balance of corrosion resistance, machinability, and formability. Its versatility and performance under stress make it ideal for precision parts with complex designs and high-performance requirements.

Need CNC Machining for AL6061?

Creallo is the first in Korea to offer real-time CNC machining quotes. Trust us to deliver top-tier quality and fast lead times with the help of AI technology and big data. Experience the difference with Creallo.

Learn more about Creallo's CNC machining services >>

View supported CNC materials >>

Explore Creallo's CNC portfolio >>