Aluminum and Anodizing

Anodizing is a surface treatment technology that artificially generates an oxide film to protect the metal surface. Among various metals, aluminum is by far the most widely anodized material, and it is not an exaggeration to say that most industrial aluminum products undergo anodizing.

Aluminum is known as a corrosion-resistant metal, but in fact, it has a high ionization tendency and reacts easily with water, oxygen, and other chemicals. When exposed to air, aluminum naturally forms a thin oxide layer. This aluminum oxide is chemically stable, resistant to acids and liquids, and does not trigger further reactions. For this reason, aluminum is commonly recognized as a “non-rusting metal.”

However, this natural oxide layer is extremely thin—about 2 nm—and can be removed with a slight scratch, exposing the base metal. To ensure long-term corrosion resistance, an artificial thick oxide film is required. This is where anodizing treatment comes in.

When aluminum is connected to the anode in an electrolytic solution, oxygen generated at the anode forms a dense oxide film. Depending on the type, this anodized film can range from 5 to 100 μm in thickness and has a hexagonal honeycomb-like structure, significantly improving durability and performance.

Types of Aluminum Anodizing

1. Hard Anodizing

- Focused on functionality such as surface hardness, wear resistance, and corrosion resistance

- Commonly applied to machine parts, industrial equipment, automotive, and aerospace components

2. Decorative (Soft) Anodizing

- Designed to prevent corrosion and enhance aesthetics through coloring

- Produces thinner and softer oxide films compared to hard anodizing

- Can create matte surfaces when combined with bead blasting

Advantages of Aluminum Anodizing

- Enhanced surface hardness: From Hv20–150 (raw aluminum) to Hv200–600 after anodizing

- Excellent wear resistance: Integrated with the base aluminum, unlike plating or painting which may peel off

- Superior corrosion resistance: Maintains performance even in harsh environments

- Premium appearance: Allows diverse colors and surface finishes

- Electrical insulation: The oxide film is non-conductive, ideal for components requiring insulation

Disadvantages of Aluminum Anodizing

- Difficult post-processing: Cracks may form if drilling or bending is performed after anodizing

- Limited heat resistance: Above 100°C, cracks or peeling may occur

- Poor resistance to sudden temperature change: Susceptible to expansion, contraction, and deformation

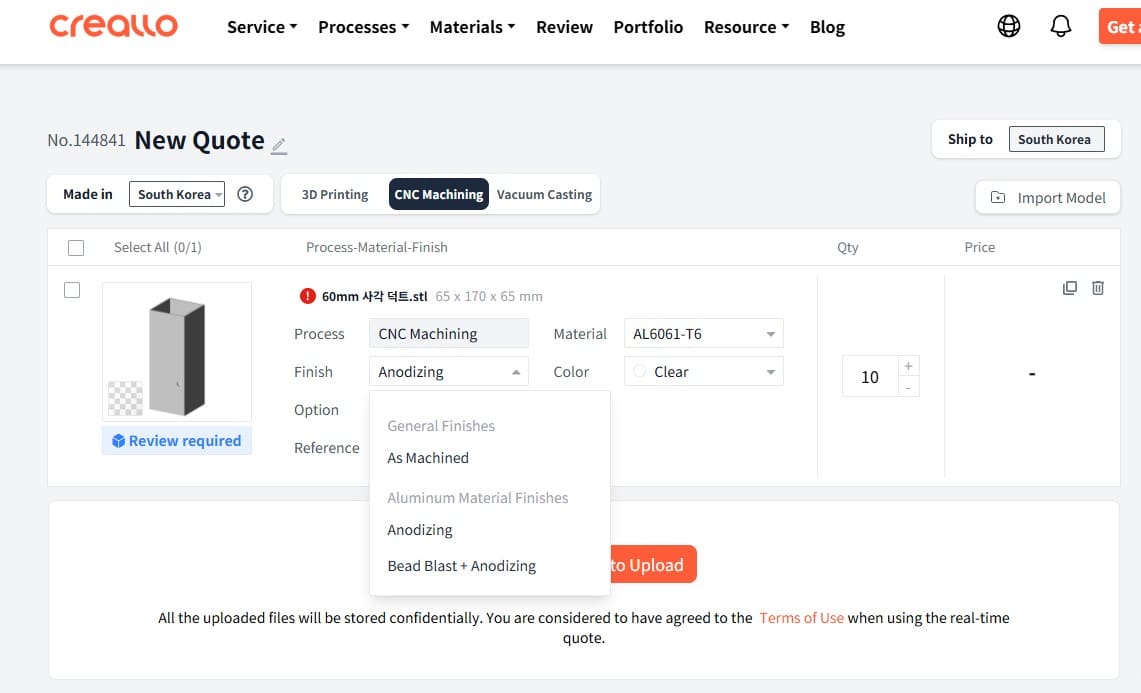

Anodizing Aluminum Machining with Creallo

Creallo provides the real-time CNC machining quotation system, including anodizing finishing options.

No more wasting time sourcing suppliers, requesting quotes, or comparing prices. Upload your 3D file, and in just minutes you can get instant DFM analysis, quotation, and order processing.

Start online manufacturing with Creallo now!

Learn more about Creallo CNC Machining Services →

View full list of finish options supported by Creallo →

.jpeg)