RobotWorld 2025 On-site Report: Creallo Showcases the Future of AI-driven Manufacturing

AUTHOR: Creallo Marketing Team|2025.11.14

The largest robotics exhibition in Korea, RobotWorld 2025, was held from November 5 to 8 at KINTEX in Ilsan.

This year’s event featured 325 companies from 17 countries, 1,027 booths, and attracted a total of 46,226 visitors and buyers, highlighting the continued growth of the global robotics industry.

Following the strong interest Creallo received at RobotWorld 2024, the company returned for the 20th anniversary edition of the event with even more advanced manufacturing solutions and high-quality samples.

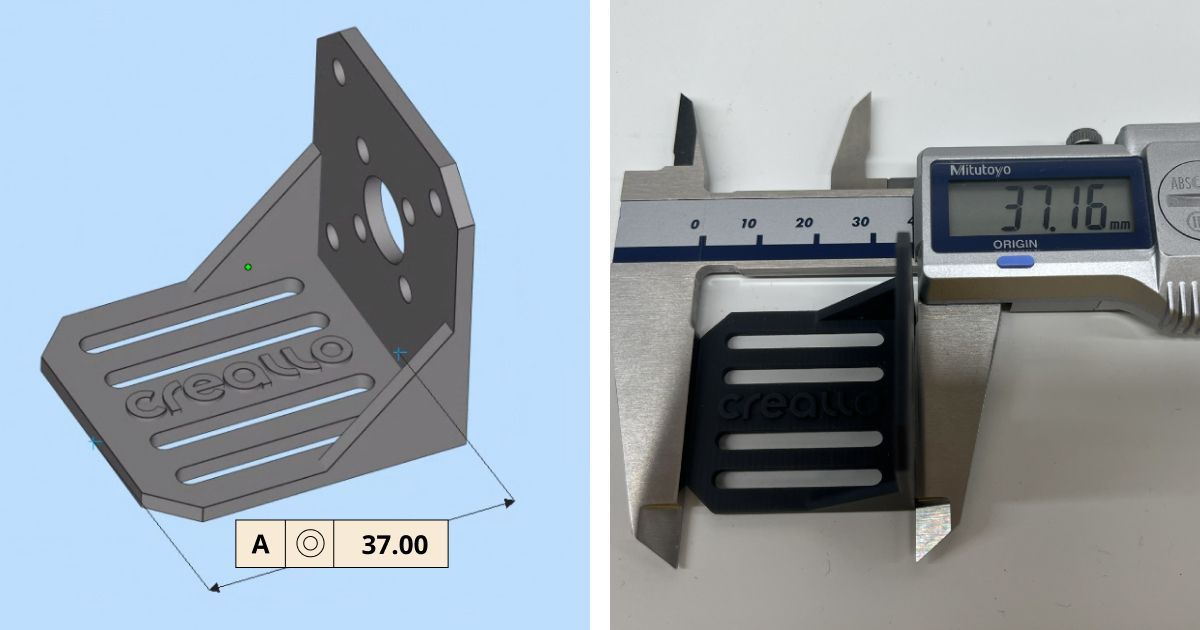

At this year’s exhibition, Creallo presented its AI-powered real-time DFM (Design for Manufacturability) analysis and instant quoting system, along with its multi-process online manufacturing services, including SLA, SLS, SLM 3D printing, CNC machining, vacuum casting, and sheet-metal fabrication.

Strong Interest in AI-driven Manufacturing and Multi-process Capabilities

Creallo demonstrated its AI-based real-time design analysis & instant quoting system, as well as its wide range of manufacturing processes such as SLA·SLS·SLM 3D printing, CNC machining, vacuum casting, and sheet-metal fabrication.

Domestic and international visitors showed strong interest in the system’s ability to automatically analyze uploaded CAD files and instantly provide manufacturability checks, cost estimates, and lead times. Many industry professionals noted that Creallo’s support for multiple processes—not only 3D printing but also CNC, vacuum casting, and sheet-metal—significantly improves efficiency from prototyping to pre-production.

Creallo’s industrial-grade SLS samples produced using EOS technology also received positive feedback, particularly for their durability, strength, and ability to realize complex geometries without support structures. Companies that previously relied on overseas vendors expressed satisfaction that equivalent production quality is now available domestically through Creallo.

High Interest from International Visitors

During the exhibition, Creallo also received a notable number of inquiries from international visitors regarding service availability in regions outside Korea. This confirmed growing global interest in Creallo’s AI-driven manufacturing capabilities across markets in Asia, North America, and Europe.

Trusted Industrial Post-processing and ISO-based Quality & Security

Creallo’s industrial post-processing capabilities also drew significant attention. Samples finished through professional processes—including sanding, painting, and surface treatment—demonstrated injection-mold–level quality, receiving high praise from robotics and industrial equipment companies.

Creallo maintains consistent quality through its ISO 9001–certified quality management system, which governs the entire production workflow—from printing and machining to finishing, inspection, and packaging. This ensures reliable repeatability not only for prototypes but also for early-stage production.

From a security standpoint, Creallo operates under ISO 27001 (Information Security Management System), ensuring that all sensitive design files and project data are managed according to international information-security standards. This has strengthened trust among customers in robotics, medical devices, and industrial equipment, where confidentiality is paramount.

Faster and More Reliable Development Through AI + Manufacturing Infrastructure

RobotWorld 2025 demonstrated Creallo’s ability to combine AI technology with advanced manufacturing infrastructure, setting a new standard for online manufacturing services.

Creallo will continue to support companies across robotics, industrial machinery, medical devices, and other sectors with faster, more efficient, and reliable manufacturing solutions.

Experience Creallo’s Online Manufacturing Services today!

- Explore AI-powered real-time DFM analysis & instant quoting→

- View supported manufacturing processes→

- See Creallo’s manufacturing case studies→