3 Effective Ways to Reduce Mold Costs – A Practical Strategy for Lowering Product Development Expenses

AUTHOR: Creallo Marketing Team|2025.06.15

Molds are precision tools used to manufacture large quantities of identical products. In fact, most everyday products are made using molds.

Since mold production accounts for a significant portion of total development costs, reducing this expense is key to improving product competitiveness.

What Is a Mold? – The Cornerstone of Manufacturing

A mold is a tool used to shape materials such as metal or plastic into specific forms. It plays a crucial role in many industries—automotive parts, electronics, appliances, and plastic packaging are just a few examples.

Mold Structure and Technology

Molds typically consist of two main parts: the fixed upper mold (core side) and the movable lower mold (cavity side). Material is injected between these plates to form the desired shape. They are used in a wide range of manufacturing methods, including injection molding, casting, extrusion, and vacuum forming.

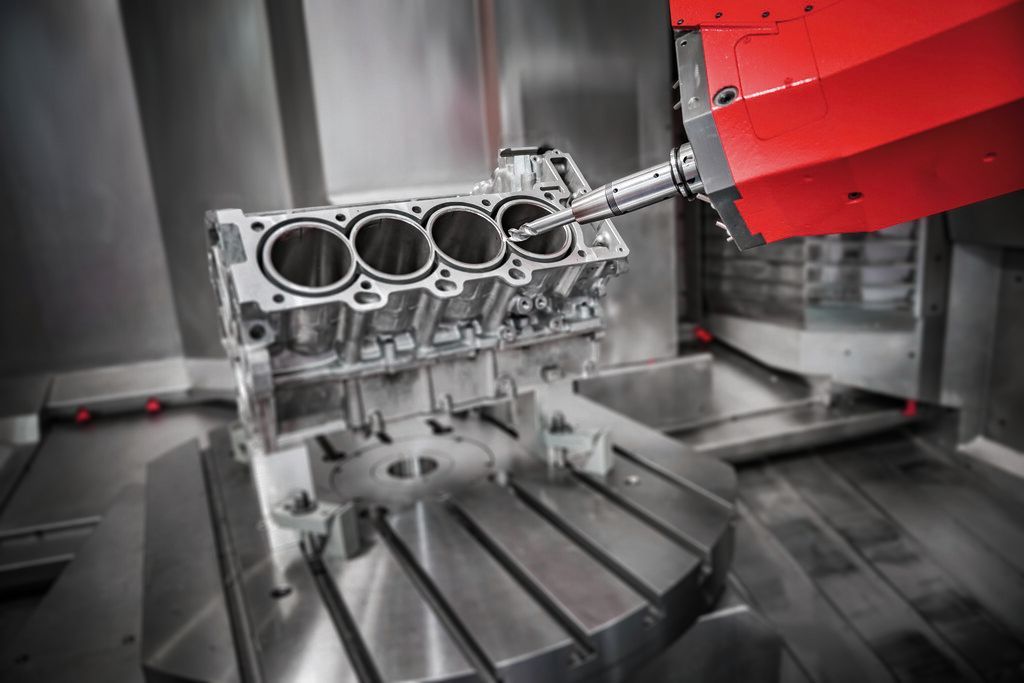

Creating high-quality molds requires precise design and machining techniques. Engineers first design the mold using CAD (Computer-Aided Design) software, and then manufacture it using CNC (Computer Numerical Control) equipment. Since tolerances can be as small as 0.01mm, this process demands highly skilled labor and state-of-the-art equipment.

Why Reducing Mold Costs Matters

Lower Production Costs

Mold fabrication is one of the most expensive steps in early-stage product development. Since molds are custom-made and highly precise, unit prices can be high. By reducing mold costs, you can significantly lower your product’s production cost and recover your investment faster.

Competitive Pricing

High mold costs increase unit prices, potentially making your product less competitive. Efficient mold cost management allows you to offer lower prices, strengthening your market position.

Faster Product Development & Launch

Streamlined mold processes result in faster development cycles. A simplified mold design or fewer revisions can speed up production, helping you bring your product to market sooner and capture early market share.

Adaptability to Low-Volume, High-Mix Production

Modern markets demand flexibility. Lower mold costs enable quicker design changes and small batch production, helping your business stay agile and responsive to market trends.

Improved Product Quality and Consistency

Molds are directly linked to dimensional accuracy and surface finish. A well-made mold reduces the defect rate, ensuring consistent quality across large production runs. This helps maintain customer trust and lowers rework or warranty costs.

(Photo: EDM (Electrical Discharge Machining) process by Daejin Precision)

3 Practical Methods to Reduce Mold Costs

Optimize Mold Design

Efficient mold design begins in the early stages. Focus on minimizing material usage and reducing machining complexity. Avoid complex shapes, undercuts, and slide cores when possible—simple, clean designs are usually more cost-effective.

Choose the Right Manufacturing Process

The production method you choose directly affects mold costs. Consider your volume, cycle time, and material properties. For high-volume production, injection molding is often ideal. For small-batch runs, 3D printing or vacuum casting may be more economical.

Avoid overcomplicating your process flow—it can negatively affect assembly accuracy and part consistency.

Collaborate with Expert Mold Suppliers

Mold fabrication requires specialized knowledge and equipment. Partnering with experienced external suppliers can lower your costs. These partners bring efficiency, advanced technology, and high-quality standards—allowing your internal team to focus on design, R&D, and marketing.

Creallo: Your End-to-End Manufacturing Partner

At Creallo, we support product teams with mold production, prototyping, and mass manufacturing solutions—all under one roof.

Want to reduce mold costs but not sure where to start?

Talk to a Creallo expert today.

We’ll help you find a cost-effective, custom manufacturing strategy tailored to your product stage.

![[Media] Automation, Trust, and AI: Interview with Heejoong Kim of Creallo on the Future of Digital Manufacturing](https://admin-atch.creallo.com/c0bc0b65-9b8a-4d76-a86f-1de146f5c211_화면_캡처_2025_-27_114254.jpeg)