3D printing is being rapidly adopted across various industries, and it’s evolving beyond a simple output technology into a form of intelligent manufacturing. At the core of this transformation lies artificial intelligence (AI).

For B2B professionals involved in product design and manufacturing, AI is becoming an indispensable tool across every stage — from design optimization and material selection to real-time quality control and production planning. In this article, we explore real-world applications and examples that illustrate how AI is revolutionizing 3D printing.

1. Automated Design Optimization: Lighter, Stronger, and More Sustainable

1. Automated Design Optimization: Lighter, Stronger, and More Sustainable

AI enables generative design by automatically generating and evaluating thousands of design alternatives based on input parameters such as load, space constraints, and materials.

- Generative design produces complex geometries that would be difficult to design manually while significantly reducing material usage. For instance, GE Aerospace used AI-powered design to reduce the weight of jet engine components, improving fuel efficiency. (Source: 3D Industry)

- Topology optimization goes a step further by reshaping parts to align with stress distribution, maintaining strength while minimizing weight. This not only enhances mechanical performance but also contributes to carbon footprint reduction — a key priority in sustainable manufacturing.

These design technologies are now applied beyond metal 3D printing. High-performance plastic parts made via SLS 3D printing benefit greatly from AI-driven optimization, with applications spanning industrial machinery, electronics, and medical devices.

2. Real-Time Quality Control: Reducing Errors and Increasing Yield

Because 3D printing builds objects layer by layer, even minor errors during the process can result in significant defects. AI mitigates this by monitoring and correcting issues in real-time.

- By analyzing sensor and camera data, AI detects errors like layer separation, nozzle clogging, or temperature deviations and automatically adjusts printer settings. Leading industrial 3D printer manufacturer EOS has integrated AI-powered in-situ monitoring to detect anomalies during laser processing, enabling automated corrections and reducing rework. (Source: EOS)

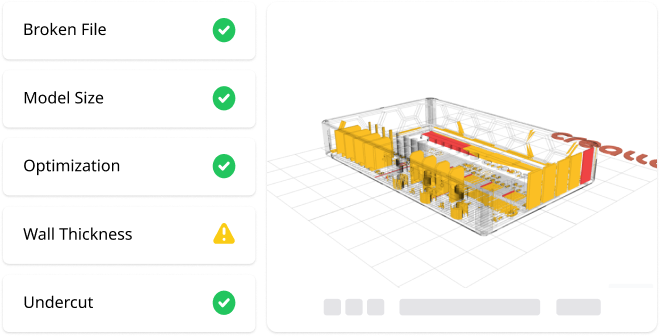

- AI also automates 3D model file repair, identifying and fixing common STL errors such as mesh gaps and overlapping surfaces. For example, Creallo’s AI-powered real-time DFM (Design for Manufacturability) analysis allows users to upload their 3D files and instantly receive a feasibility report. Complex geometries or unsupported features are flagged immediately, helping B2B developers reduce prototyping failures and accelerate development timelines.

3. Custom Design and Material Selection: Enabling User-Centric Manufacturing

AI enables personalized design and material recommendations based on user-specific data.

- In healthcare, AI analyzes CT or MRI scans to design custom implants and assistive devices tailored to individual patients. Medical device companies are increasingly using AI-driven modeling for patient-specific prosthetics. (Source: Science Direct)

- In consumer goods, Adidas used AI to analyze customer foot shapes and movement patterns, creating fully customized 3D-printed shoes. (Source: The Verge) Another example is Syntilay, a U.S.-based startup that combines AI-generated design with 3D printing to produce shoes tailored to each customer’s foot, based on smartphone scans.

4. Smarter Production Planning: Predict and Optimize with AI

AI plays a vital role in predictive maintenance and process optimization in 3D printing.

By analyzing data from sensors — including vibration, heat, and deposition speed — AI can detect signs of wear or malfunction in equipment and recommend timely maintenance before failures occur.

AI also proposes the most efficient print paths, material usage, and energy settings, reducing waste and cost.

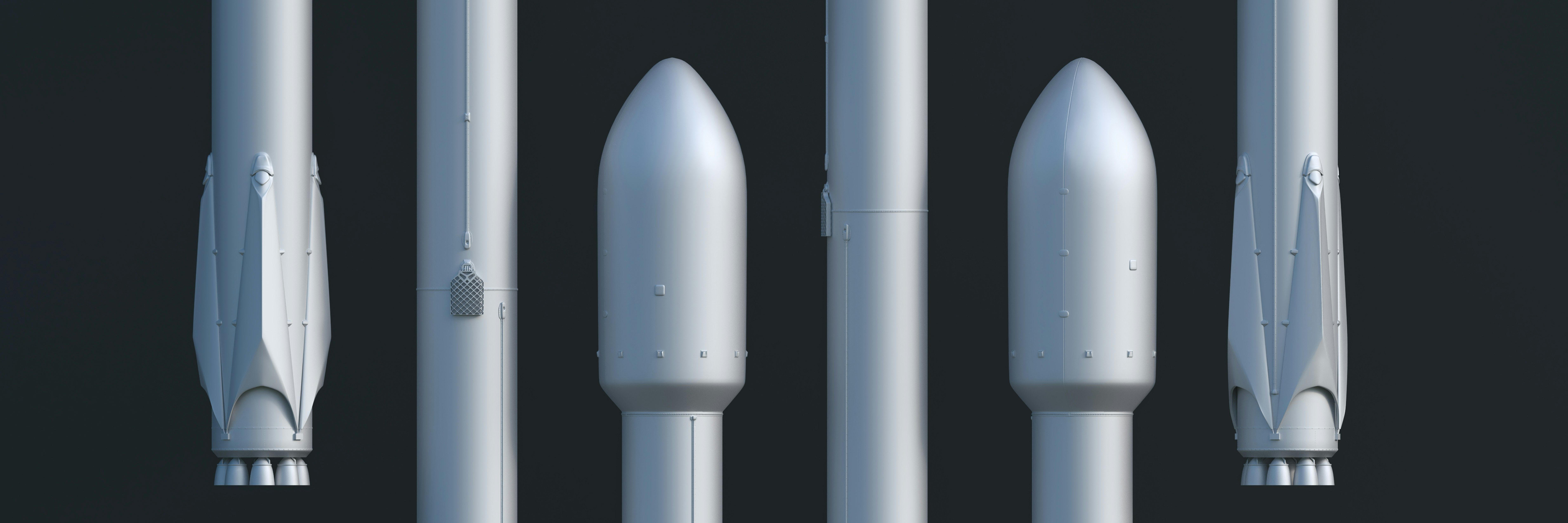

Companies like Relativity Space leverage AI to optimize rocket part production, cutting costs while improving agility.

AI: A Strategic Driver, Not Just a Tool

AI is not just a productivity booster — it's becoming a strategic enabler for next-generation manufacturing.

From intelligent design and in-process monitoring to tailored user experiences and predictive maintenance, AI enhances every step of the 3D printing workflow.

For B2B designers and manufacturers, AI is no longer a “future technology.” It’s an essential, real-world solution that improves efficiency and success rates.

At Creallo, we integrate AI across the product development lifecycle — from automated manufacturability checks to instant quoting and fast, reliable production. With AI, you can reduce lead time, lower development costs, and minimize risk.

???? Ready to experience smart manufacturing powered by AI?

![[Media] Automation, Trust, and AI: Interview with Heejoong Kim of Creallo on the Future of Digital Manufacturing](https://admin-atch.creallo.com/c0bc0b65-9b8a-4d76-a86f-1de146f5c211_화면_캡처_2025_-27_114254.jpeg)