Pushing the Limits of Complex Manufacturing – Real-World Applications of SLS 3D Printing

AUTHOR: Creallo Marketing Team|2025.07.23

Complex Designs, Rapid Development, and Customized Production – How SLS 3D Printing Meets the New Demands of Modern Manufacturing.

Manufacturing is now at a pivotal point of technological transformation. As markets and customer demands continue to evolve rapidly, the need for high-precision parts, small-batch and high-mix production, and sustainable manufacturing has grown significantly. In this landscape, SLS (Selective Laser Sintering) 3D printing stands out as a solution that overcomes the limitations of traditional methods—offering greater design freedom and production flexibility.

This article introduces real-world case studies from industries such as consumer goods, aerospace, automation, and medical devices that have successfully adopted SLS 3D printing to enhance productivity and drive innovation.

(Reference: Customer Case Studies | EOS GmbH)

Explore Creallo’s SLS 3D Printing Services>

Innovation in Industrial Manufacturing – How EOS SLS Technology Is Transforming Diverse Industries

Breezm – Achieving Precision, Productivity, and Customization with 3D Printing

Korean eyewear startup Breezm aimed to deliver truly customized glasses tailored to each customer. However, traditional eyewear manufacturing—which required a six-month production cycle and a minimum order quantity of 300 to 500 pairs—was incompatible with Breezm’s on-demand business model.

With EOS SLS 3D printing, Breezm was able to manufacture glasses with personalized fit and aesthetics at scale.

Key achievements include:

- One-to-one customized designs using facial scan data

- 60% annual revenue growth through improved production efficiency

- Time-to-market accelerated by 5x, reducing production cycles from 6 months to 3–4 weeks

- Over 80 unique designs offered in five color options

- More than 60,000 pairs produced to date

Eliminating minimum order quantities allowed Breezm to offer highly customized eyewear without inventory risk. Meanwhile, fast production enabled them to stay competitive in the fast-changing fashion and consumer goods markets.

We no longer rely on mass production. Now, we manufacture for each individual customer.

— Seong Woo-Seok, CEO, Breezm

Festo – Lightweight Precision Components for Bionic Drones

Festo, an industrial automation company, is developing a new era of robotics through its bionic drone series inspired by biological movements.

One project, the BionicBee, required ultra-light and precise components that were nearly impossible to produce using conventional injection molding or CNC machining.

By adopting SLS 3D printing, Festo successfully created intricate lattice drone frames:

- Ultra-precise lattice structures enabled

- Weight reduced from 12g to 3g—a 75% decrease

- Enhanced flight stability and energy efficiency

- Swarm flight with 20 autonomous drone units achieved

- Established a foundation for even more complex lightweight designs

SLS 3D printing accelerated rapid prototyping and on-demand production, helping Festo dramatically shorten its development cycles and push innovation forward.

LMD – Automation Baking Gripper for Flexibility, Hygiene, and Efficiency

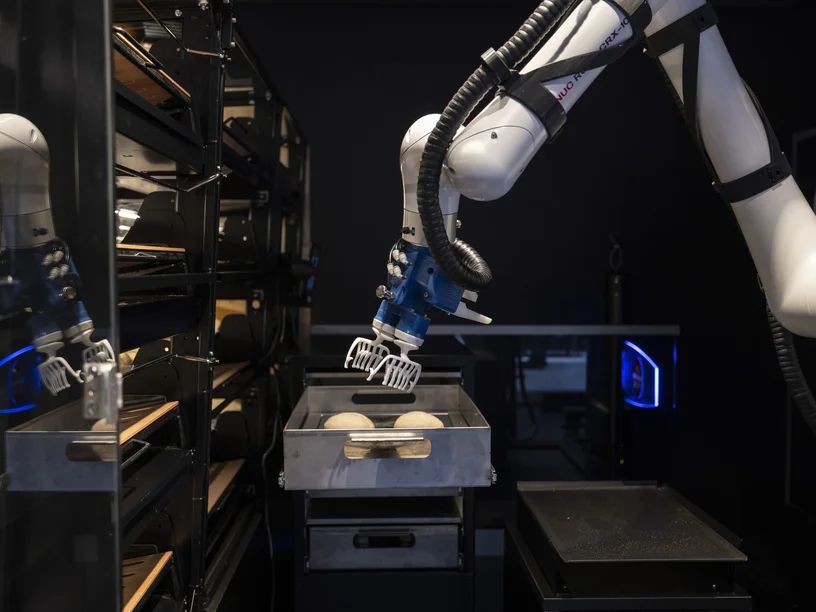

German automation startup LMD developed ‘Bakisto,’ an AI-powered automated baking system to address labor shortages and food waste. A key component is a lightweight hygienic gripper made with EOS SLS 3D printing.

In bakery automation, tools must handle delicate items, meet hygiene standards, and enable quick tool changes. Traditional metal grippers were heavy and restricted in movement due to external hoses and cables.

By integrating SLS 3D printing, LMD achieved:

- Built-in pneumatic channels, reducing failure points and simplifying cleaning

- A fully automated system capable of 24/7 operation

- Rounded and flexible design, minimizing collision risks

- Safe handling of fragile items like croissants

- Waste reduction and consistent product quality

Thanks to functional integration and lightweight design, LMD created a more compact system that saves both space and cost.

Kuhn-Stoff – Functional Bronchial Gripper with Lightweight Base Plate

Kuhn-Stoff aimed to create a gripper that was lighter yet strong enough to handle required loads. Reducing weight was essential to improve energy efficiency and system durability.

By simplifying the design and optimizing the structure with SLS 3D printing, Kuhn-Stoff achieved:

- Single-piece production without post-processing or assembly

- Reduced part count from 21 to just 2

- 86% weight reduction to 220g

- Reliable performance under continuous and demanding use

- Production time shortened from 12 days to 3 days

- 50% reduction in manufacturing costs

This resulted in a strong, lightweight bronchial gripper with an integrated functional base plate.

Atlas Copco – Simplifying Complex Automation Parts to Save Time and Costs

Atlas Copco produces rivet feed bowls—key components for self-piercing rivet systems used in the automotive industry. Facing common modern manufacturing issues like long lead times, supply chain disruptions, and rising production costs, the company turned to SLS 3D printing.

With EOS technology, Atlas Copco achieved:

- Lead time reduced by 92%, from 6–12 weeks to just 3–4 days

- 30% reduction in production costs by eliminating outsourcing and labor hours

- Material waste dropped from ~7% to near-zero

- Greater agility in responding to urgent customer requests

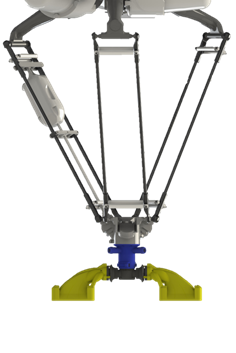

Anubis 3D – Lightweight, High-Performance Robotic EOATs

Anubis 3D specializes in custom EOATs (end-of-arm tools) for industrial robots. Their challenge was to meet customers’ need for flexible design and fast turnaround—while keeping tool weight below 2kg to maintain the robot’s speed and balance.

With EOS SLS 3D printing, Anubis 3D realized:

- Greater design complexity, enabling weight optimization and functional integration

- Over 70% weight reduction compared to metal

- Gripping performance improved by more than 4x

- Full design, production, and testing cycle completed within a week

Ortoplus – Mass Customization of Medical Devices

Spanish medical device company Ortoplus specializes in custom oral appliances for sleep apnea. Treatments like night guards can be expensive, time-consuming, and uncomfortable, often leading to poor patient compliance.

After adopting biocompatible materials and EOS SLS 3D printing, Ortoplus achieved:

- Improved quality of life for over 75,000 patients worldwide

- Comfort-enhanced appliances with dimensional accuracy under 0.1 mm

- 300% increase in production capacity without additional staffing

- Reduced human error through more flexible digital design workflows

Making Innovation a Reality with SLS 3D Printing

SLS 3D printing has evolved beyond prototyping—it's now a core technology for volume production and design optimization.

B2B manufacturers are facing increasingly complex challenges: intricate designs, growing demand for customization, and shorter lead times. In this environment, industrial 3D printing services offer an ideal solution—enabling rapid validation, iterative design, and waste-free production.

Creallo has taken the lead in this transformation by becoming the first in the Asia-Pacific region to introduce EOS’s next-generation SLS system, the P3 NEXT. This advancement enables even faster and more precise innovation in B2B manufacturing.

From prototyping to full-scale production, bring your design to life with Creallo’s fast quoting, high-performance eco-friendly materials, and precision print quality.

![[Endorobotics x Creallo] Realizing Complex Medical Robot Simulator Parts with 3D Printing](https://admin-atch.creallo.com/ea89e979-7d47-4534-ad74-3e97ae5df146_Endorobotics_logo.jpeg)